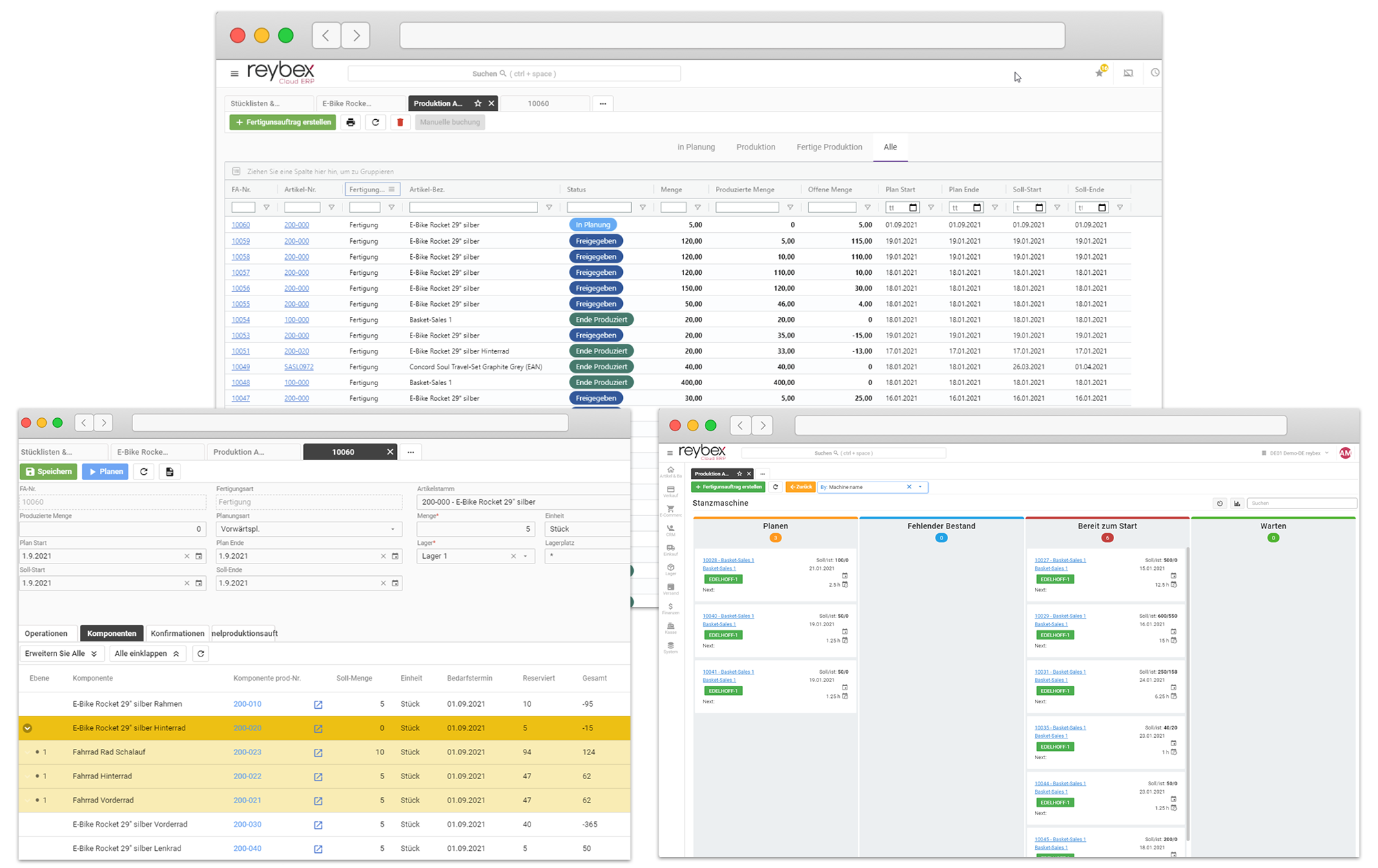

Production planning and production control integrated in your ERP system

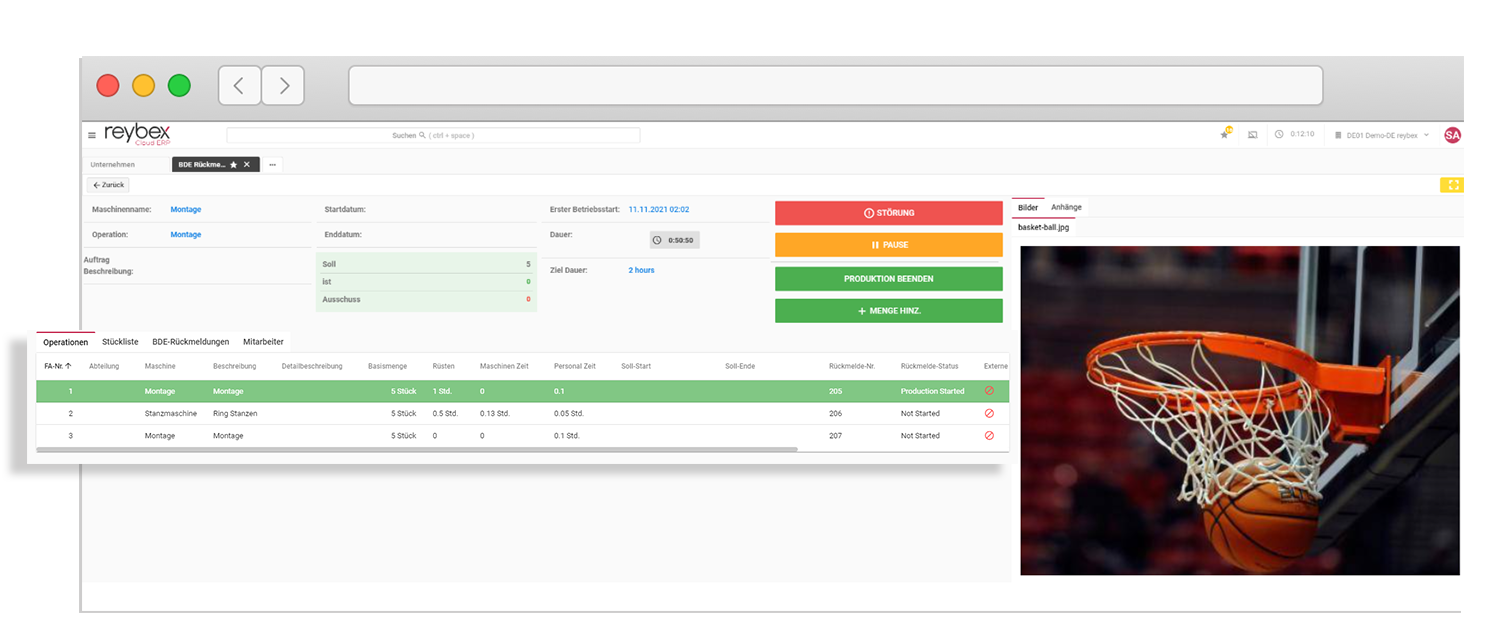

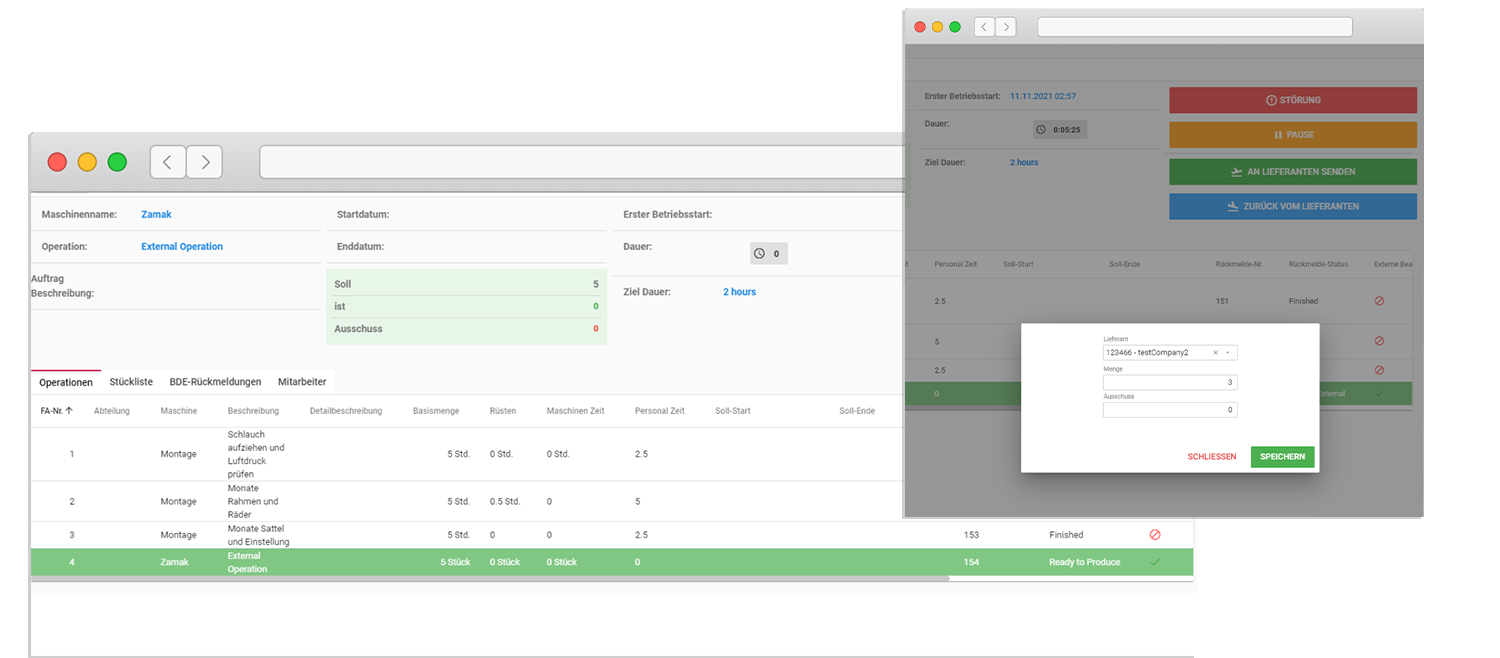

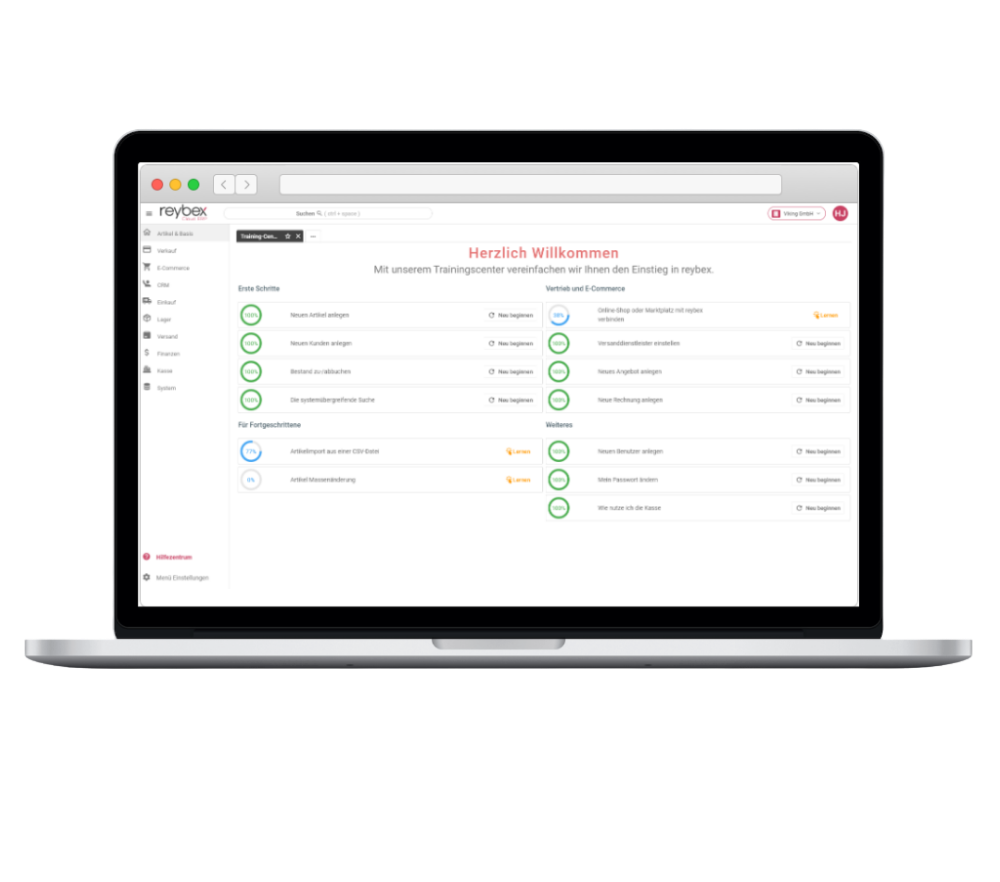

With reybex, you have a complete overview of your production. With its intuitive and simple operation, mapping your production planning and production control is no longer rocket science.

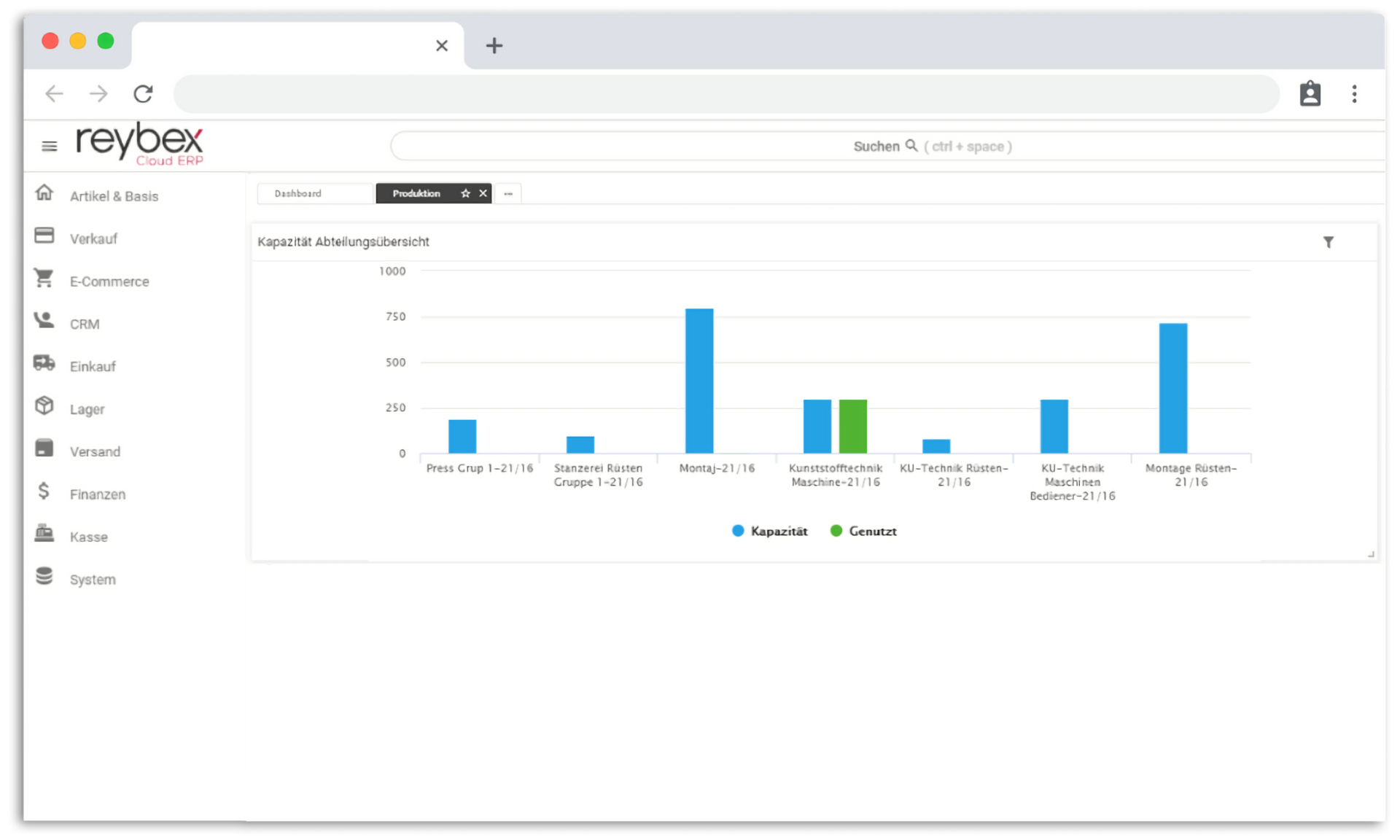

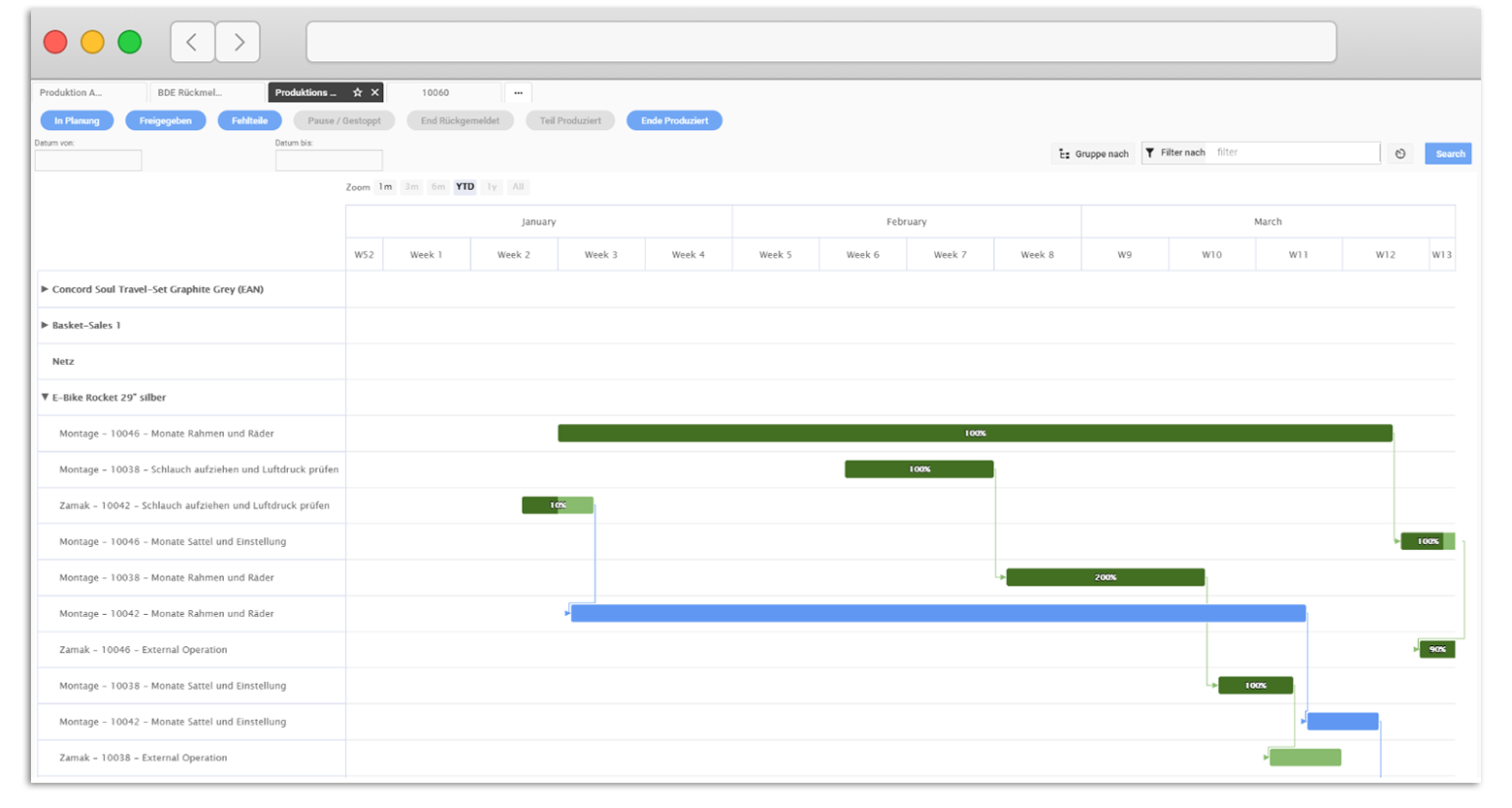

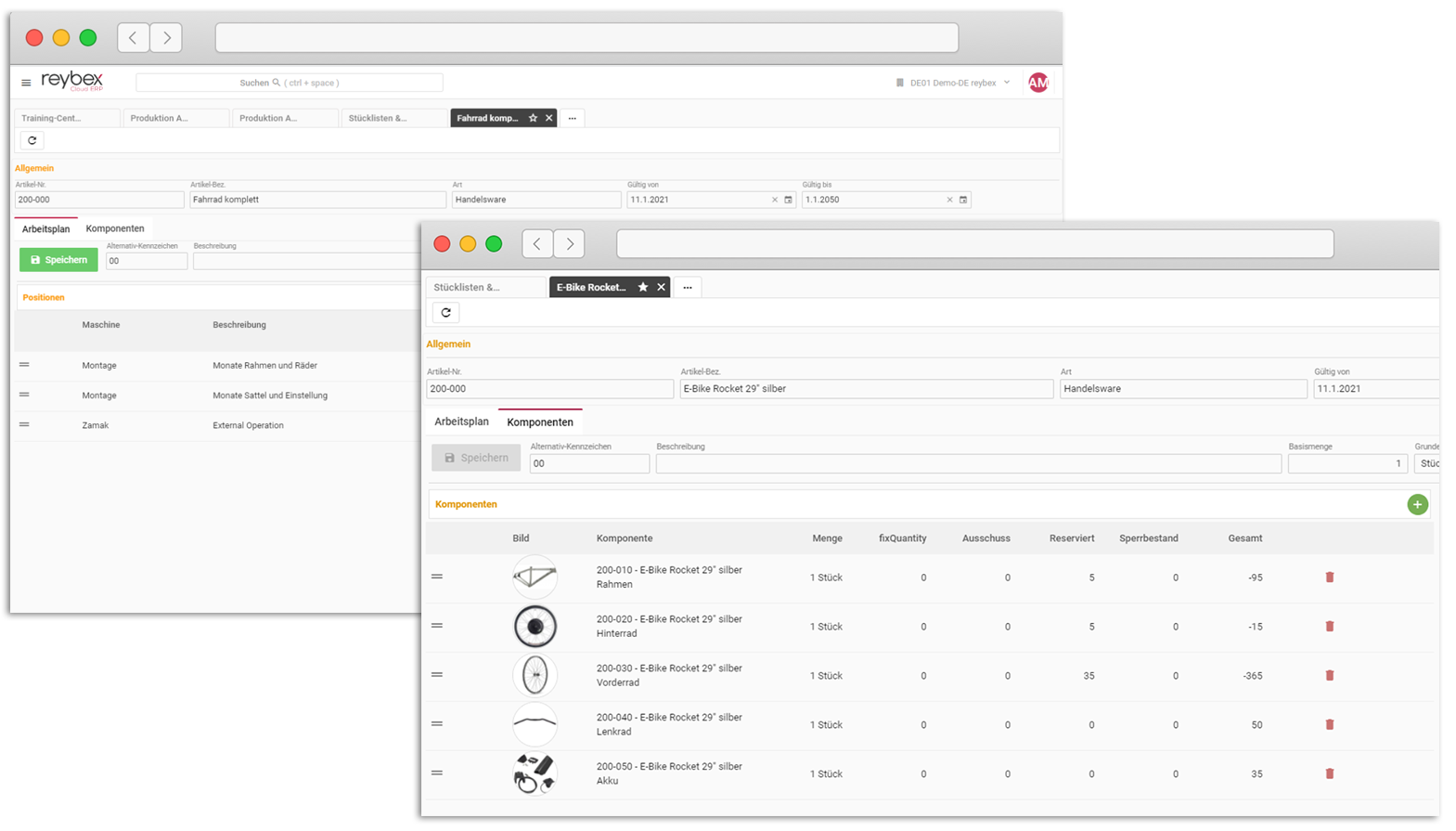

Thanks to full integration with other reybex modules such as article master, inventory management and MRP (material requirements planning), as well as a transparent data flow, your departments work together effectively and in a coordinated manner. Optimize your delivery reliability through transparent capacity planning and a scheduling run that identifies and schedules all requirements at an early stage and on a daily basis.

The reybex production module consists of the following core components: